Employee tracking in manufacturing is a vital practice for enhancing productivity, safety, and overall efficiency. Modern technology, such as BLE Beacon, LoRaWAN, RFID systems or wearable devices, allows manufacturers to monitor the movements, performance, and attendance of their workforce. By collecting data on employee activities, manufacturers can optimize workflows, reduce downtime, and ensure compliance with safety regulations. Employee tracking also aids in identifying training needs, managing work schedules, and evaluating individual and team performance. This data-driven approach not only improves production processes but also fosters a safer and more organized work environment.

People tracking in manufacturing involves monitoring the location and activities of employees using technology like LoRaWAN, BLE Beacon and RFID or GPS. This practice enhances safety, productivity, and resource management. It helps prevent accidents, optimize workflows, track attendance, and improve workforce efficiency, ultimately contributing to the success of manufacturing operations.

proximity to machinery and potentially hazardous areas. This helps prevent accidents and ensures compliance with safety protocols.

By providing real-time insights into employee movements and work patterns. Manufacturers can identify bottlenecks, improve resource allocation, and streamline workflows, leading to increased output and reduced downtime.

By accurately tracking attendance, break times, and work hours. This ensures fair and accurate payroll processing and helps manage workforce availability effectively.

and individual training needs identification, resulting in a more skilled and motivated workforce.

with industry regulations and quality standards, reducing the risk of costly fines and production disruptions. In summary, employee tracking in manufacturing plays a crucial role in improving safety, productivity, resource management, and compliance while fostering a more informed and efficient workforce.

play a crucial role in monitoring and tracking employees in manufacturing, offering a range of benefits. They provide real-time insights into workforce movements, enabling manufacturers to enhance safety by issuing warnings when employees approach hazardous machinery. Additionally, IoT devices help in managing attendance, break times, and work hours accurately, streamlining payroll processes and workforce management. They also aid in compliance with safety regulations and industry standards, reducing the risk of costly fines and production disruptions. Overall, IoT devices empower manufacturers with data-driven decision-making capabilities, fostering a safer, more efficient, and competitive manufacturing environment.

WristbandKeyfob_Beacon

WristStrap_Beacon

temperature_Beacon

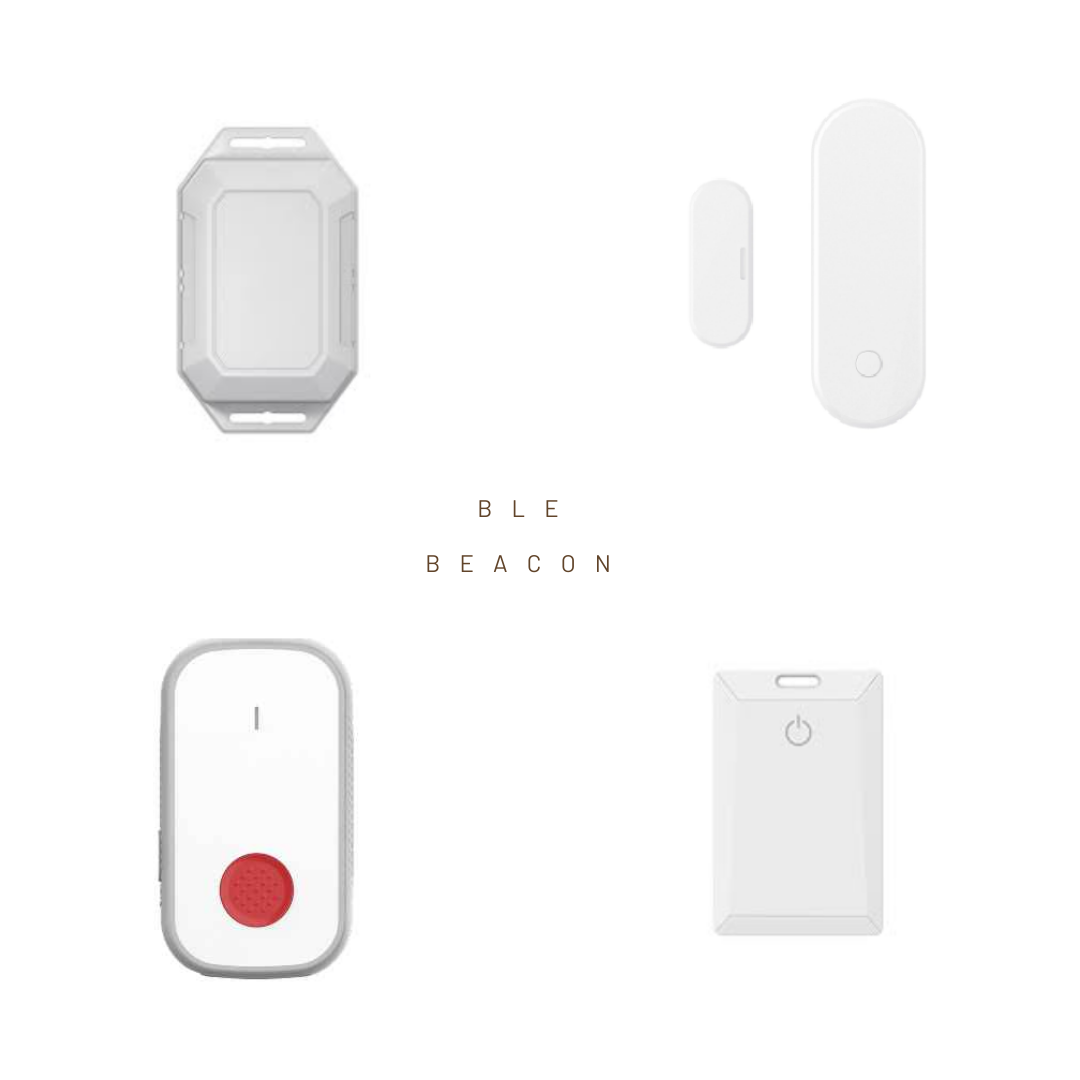

People tracking in manufacturing using Bluetooth Low Energy (BLE) beacon technology has become an increasingly important tool in optimizing safety, efficiency, and productivity on the factory floor. BLE beacons are small, battery-powered devices that emit Bluetooth signals at regular intervals, and by leveraging these signals, manufacturers can track the movements and activities of their employees and visitors within the facility.

LoRaWAN (Long Range Wide Area Network) is a wireless communication technology that has found applications in various industries, including manufacturing, for people tracking. Here’s how LoRaWAN can be utilized for people tracking in manufacturing:

LoRaWAN technology offers a cost-effective, long-range, and scalable solution for people tracking in manufacturing, promoting safety, efficiency, and resource management within the facility. It has become a valuable tool for modern manufacturing operations seeking to optimize their workforce and enhance overall productivity.

Wirepas is a wireless communication technology and a mesh networking protocol that can be used for people tracking in manufacturing. Here are some key considerations when using Wirepas for this purpose:

Wirepas is a versatile solution for people tracking in manufacturing, offering the benefits of real-time tracking, scalability, low power consumption, and location accuracy.